As an industry, we have been set many challenges with regards to the UK’s ambitious 2050 net-zero target combined with delivering 300,000 new homes per annum. In addition, we are also making inroads to developing our new build homes to meet the Future Homes Standard which is set to come in 2025.

In preparation for this, Part L Building Regulations will be updated and enforced in June 2022. This is a stepping stone and a transitional period in the lead-up to the Future Homes Standard in 2025.

What is Part L?

Building Regulations Part L primarily focuses on the conservation of fuel and power, As it stands, up to 30% of heat lost in a building is through the fabric of the building which has led to the introduction of the Target Fabric Energy Efficiency (TFEE) rates. This has led to a shift into ensuring that the fabric of the building is the key consideration at the design phase to ensure there is adequate insulation and a significant reduction in thermal bridging.

What is SAP?

A SAP Calculation is a desktop exercise that is undertaken during the design process and delivers a predicted EPC for new homes. It’s a set target that housebuilders can meet through substituting various materials and build methods.

Within this calculation, there is an increased focus on the thermal performance of the ‘fabric’ of the building including the walls, roof, floor and lintels, elements that are unlikely to change during the lifespan. The fabric is an element of the SAP calculations sits alongside other factors that are much more flexible such as lighting, low carbon heating and hot water generation.

What is TFEE?

TFEE stands for ‘Target Fabric Efficiency’ and specifically looks at the energy efficiency of a new build home with regards to airtightness and cold bridging.

What are the changes to Part L compliance?

Many UK housebuilders have already accepted the challenge and are now actively switching to energy-saving alternatives such as thermally broken lintels before looking at costly alternatives such as heat pumps, solar panels and triple glazing. Taking a fabric first approach is a sustainable and proven low-cost solution to reducing carbon emissions.

What impact can thermally broken lintels have?

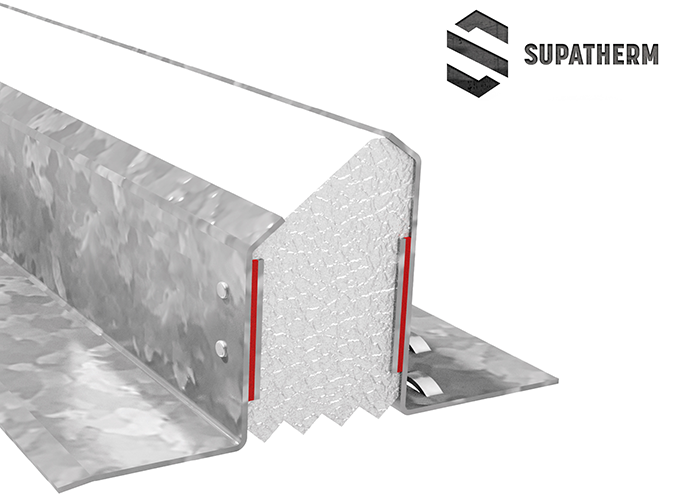

Our Supatherm range of thermally broken lintels can deliver a 75% reduction in heat loss compared to standard lintels. To put this into perspective, this means that a small detached house (105m2) substituting standard lintels with thermally broken lintels could deliver the same results as upgrading to triple glazing. On a large detached dwelling (304m2) it would enable a cavity wall reduction from 150mm to 125mm delivering savings on insulation and masonry ancillaries.

or