Lintels are a load-bearing structural element that spans the opening between two vertical supports. They are most commonly used to support the wall above doors and windows and come in all sorts of shapes and sizes. For instance, they range from Juliet balconies through to large grand openings including on trend bi-folding doors. We can design lintels to meet the load-bearing requirements of any project, including some decorative bespoke designs.

We’ve made this really easy. Our Psi value calculator instantly presents the thermal transmittance of our Supatherm range of lintels. All a customer needs to do is input the cavity width, block and insulation details, along with lintel length. From this information, the calculator provides Psi value in W/mK.

The result is really easy to understand, – it’s just like a U value, the lower the Psi, the better the thermal performance you get from the lintel. For optimum thermal efficiency, look for a lintel with a Psi between 0.041 and 0.073 W/mK. You can find this online tool here

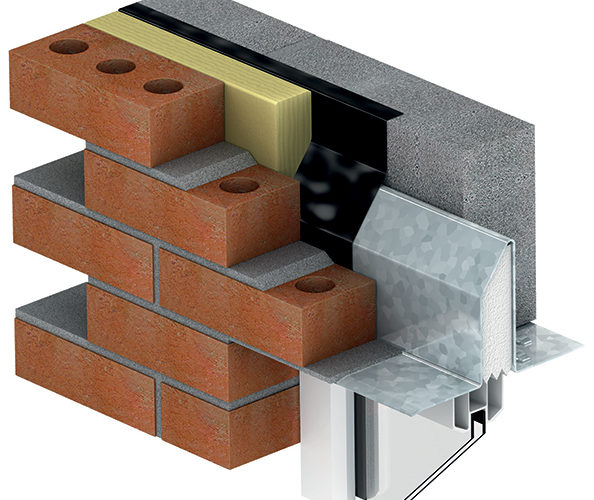

Choosing the right lintel is important because it can improve the energy efficiency of the whole building. For instance, traditional single piece lintels don’t have a thermal break and that allows the transfer of heat to the outside.

It’s similar to placing a spoon in a hot drink – heat transfers up the shaft causing the drink to cool down faster. A single piece lintel works in much the same way, drawing heat out of the room through thermal bridging. Decoupling the internal half of the lintel from the outside, like with our Supatherm range, reduces heat transfer through thermal bridging.

With a typical dwelling having 8-10 windows and two doors, thermal bridging through a traditional single-piece lintel can account for around a third of the total heat loss from a building. That’s why getting your customer to choose the right lintel – a thermally broken range – makes a huge difference to the running costs of a property.

In the case of a small detached dwelling of around 105m², the reduction in heat loss from a thermally broken lintel is equivalent to upgrading from a double to a triple glazed window – but at a fraction of the cost! This can result in a 60% reduction in heat loss compared with the use of standard cavity wall lintels.

The impact of upgrading to a super-insulated lintel is even greater on a larger detached dwelling of 304m², because it can mean the cavity wall thickness is reduced from 150mm to 125mm. This is another significant saving for your customers in terms of insulation and masonry ancillaries. It also avoids the loss of internal living space as wider cavities have a tendency to encroach on the internal footprint.

Some lintels are manufactured using pre-galvanized material. That means the cut edges and welds have to be painted after the lintel has been fabricated, which, as you will probably know, isn’t as robust as galvanizing, so these areas are always going to be vulnerable to corrosion.

Our lintels are the only product range to be fully hot-dip galvanized after fabrication to EN1461. This results in up to 50% more zinc protection than other approved coatings. Hot Dip Galvanising to EN1461 offers superior corrosion protection and extended product lifespan compared with pre-galvanized lintels.

We are able to design and manufacture a wide range of special lintels alongside our standard range, to individual requirements. A recent project saw us design a complete lintel solution for a private bespoke ‘shell’ spiraled residential dwelling. Our technical team studied the drawings provided by the architect and created a bespoke design to support the structure. It turned out to be quite an unusual building!

Birtley offers comprehensive technical support, including pre and post-sale guidance, specification, BIM and CAD scheduling from supplied architectural plans. We also offer comprehensive advice for unusual loading situations. In addition, we can provide a design service for bespoke features and wall constructions, structural calculations and element analysis of complex structures.